Vimfun Launches Upgraded SGRIT20 Endless Diamond Wire Saw, Redefining Precision Cutting for Optical Materials

Vimfun launches the upgraded SGRIT20 endless diamond wire saw—high-speed, multi-function cutting for optical and semiconductor materials.

SHANGHAI, JIANGSU, CHINA, October 21, 2025 /EINPresswire.com/ -- Vimfun Diamond Wire Saw, a leading developer of advanced precision cutting technology, proudly introduces the upgraded Vimfun SGRIT20 Endless Diamond Wire Saw. This new-generation model marks a significant leap in the cutting of hard, brittle, and high-value materials such as optical glass, ceramics, silicon, sapphire, and composite materials used in high-tech manufacturing.

The SGRIT20 upgrade continues Vimfun’s commitment to innovation by combining cutting-edge mechanical engineering, optimized control systems, and advanced diamond wire design to deliver high-speed, multi-functional precision cutting in one integrated system.

1, A Closed-Loop System That Changes Cutting Standards

At the core of the SGRIT20 is an endless (closed-loop) diamond wire—approximately 3 meters in length—that moves continuously in one direction. The wire runs at speeds of up to 80 meters per second under carefully controlled tension (150–250 N). This unique design eliminates the back-and-forth movement found in traditional long-wire saws, which often leads to vibration, uneven tension, and inconsistent surface quality.

With the endless configuration, the wire operates in a stable, continuous loop that allows for smoother motion, lower vibration, and extended wire life. The result is an exceptionally fine cutting surface with minimal kerf loss—ideal for expensive and delicate materials where precision and yield are critical.

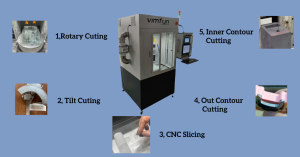

2,Five Cutting Modes, One Compact System

The SGRIT20 is designed as a multi-functional all-in-one cutting platform capable of performing:

Slicing for wafer and block sectioning

Outer contour cutting for defining complex shapes

Inner contour cutting for cavity machining

Rotational cutting for circular or cylindrical workpieces

Inclined cutting for customized geometries and angular surfaces

This versatility allows manufacturers to perform multiple processes on one machine, improving production efficiency and reducing the need for secondary finishing or additional equipment.

3,Performance and Quality Advantages

Compared to traditional reciprocating wire saws, the upgraded SGRIT20 delivers multiple measurable advantages:

Higher cutting speed and productivity, enabled by unidirectional motion and consistent wire velocity.

Reduced material loss, with a cutting kerf as narrow as 0.35 mm when using Vimfun’s 0.3 mm diamond wire.

Superior surface finish, eliminating wire marks and subsurface micro-cracks common in conventional sawing.

Simplified operation and maintenance, due to its compact design and robust control interface.

Extended wire lifespan, supported by an optimized tensioning system and stable linear dynamics.

These advantages make the SGRIT20 particularly valuable for industries where material utilization rate, dimensional precision, and surface integrity directly affect product quality and cost efficiency.

4, Proven Results in Optical and Semiconductor Applications

Vimfun’s SGRIT20 has already been successfully adopted in optical glass and optoelectronic component manufacturing, where ultra-flat and scratch-free surfaces are essential. Clients report improved process stability and significantly lower waste compared to conventional cutting systems.

The same technology has also shown promising results in semiconductor substrate cutting, graphite electrode processing, and advanced ceramic machining, where tight tolerances and micro-level accuracy are required.

5, A Step Toward Smarter Manufacturing

In addition to its mechanical advantages, Vimfun is actively integrating digital control systems into its cutting machines. The SGRIT20 platform is compatible with intelligent monitoring, allowing operators to analyze real-time cutting parameters such as wire speed, tension, and load. This capability helps prevent errors, extends wire life, and supports the broader movement toward Industry 4.0 smart manufacturing.

The upgraded model also features modular expansion ports that enable future upgrades for automation or robotic integration, providing long-term flexibility for evolving production environments.

ABOUT VIMFUN DIAMOND WIRE SAW

Vimfun Diamond Wire Saw specializes in the R&D and manufacturing of endless diamond wire cutting systems. Its technologies are designed for high-precision cutting of hard, brittle, and high-value materials such as silicon, sapphire, ceramics, graphite, and optical glass.

Vimfun’s proprietary endless wire technology offers high cutting speed, precision, and low material loss, enabling applications in semiconductors, optics, electronics, and advanced materials industries. With continuous investment in engineering and automation, Vimfun is redefining the global standard for fine cutting solutions.

For more information, visit www.endlesswiresaw.com.

Daria Xu

Vimfun Diamond Wire Saw

+1 408-571-8651

email us here

Visit us on social media:

LinkedIn

YouTube

Vimfun Diamond Wire Saw Facory Tour

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.